In recent years, large-scale factory farming in aquaculture has been on the rise. Especially since 2000, as foreign industrialized circulating aquaculture technology has begun to enter the stage of large-scale application, the research has been more in-depth, and advanced aquatic biotechnology and engineering technology have been continuously integrated and innovated and applied to this field.

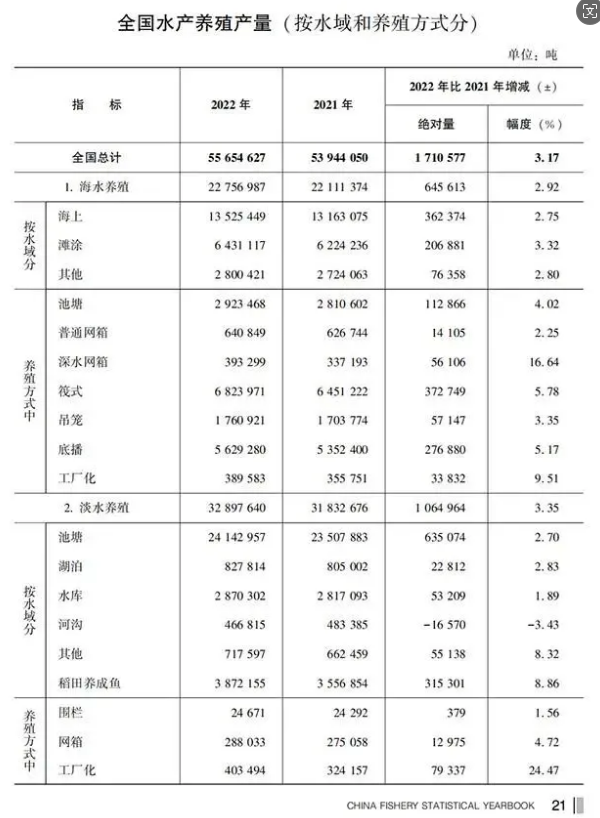

In recent years, the area and output of China's factory recirculating aquaculture have increased year by year, especially the increase in freshwater factory aquaculture is very obvious.

The factory Recirculating Aquaculture System (RAS) is composed of purification system, temperature control system, oxygenation system and sterilization and disinfection system. Through a complete set of recirculating water treatment system, it can not only kill various pathogens breeding in water bodies, but also reduce aquatic biological diseases. At the same time, it can simulate the living environment of all kinds of aquatic organisms, conduct scientific management of the living environment of cultured varieties, and reduce the restrictions of natural resources such as land and water.

So, in the era of the gradual development of factory recirculating aquaculture system, how should enterprises carry out factory recirculating aquaculture? What factors need to be considered?

Factory recirculating aquaculture system

1. Breed and density

In the early stage of designing a factory recirculating aquaculture system, we must first understand the breeding species and breeding density. Different varieties of circulating water system requirements are different, but also affect the procurement of equipment, which is a topic of opinion. If the breeding technology passes the case, priority can be given to breeding precious varieties. In recent years. South American white shrimp, Australian freshwater lobster, freshwater eel, perch, grouper, salamander, feed Mandarin fish, are quite popular varieties. Of course, when selecting cultured varieties, we should also consider the market price of this variety in the future.

In addition to breeding species, breeding density should also be considered. In general, the higher the breeding density, the greater the yield and the higher the profit. However, the corresponding high-density aquaculture has high requirements for the water environment and quality, and this is what the factory recirculating aquaculture system can do.

2. Breeding tank selection

The factory-type recirculating aquaculture model should take into account the flow pattern, velocity, self-collecting sewage and standardized design of aquaculture pond engineering. In addition, the type of breeding pond will also be considered. Under the traditional concept of aquaculture, many people would adopt a square pond. However, today, more and more factory farming fisheries will use circular aquaculture ponds. In addition, the round fish culture tank can be made of polymer plastics such as PP or PE, which is clean, injury-free and easy to manage, and has a higher cost performance than the civil square culture tank.

3. Water quality management

Feces, bait and debris are easy to clog the purification equipment, and the removal of organic matter and ammonia nitrogen generated by decomposition is difficult. It is necessary to consider the requirements of filtration efficiency, stability and automation. High-end farming models need to be accurately designed according to water quality, load, structure and other conditions to achieve high efficiency, stability and cheap.

Fish can only use 25 to 40% of the protein, the rest in the form of organic nitrogen, inorganic nitrogen, phosphate and other metabolized into the water, toxic to aquaculture organisms, and make the water eutrophication N, P. The existing biological filters, biological turntables (buckets), etc., have more components designed by experience, and the stability and efficiency of operation are worth considering, and the utilization rate of circulating water is low. The demand for high-end models is efficient, stable, and occupies a small space, which needs to be accurately designed according to the carrier and structure.

4. Water body oxygenation

Dissolved oxygen directly affects the density, purification efficiency, energy consumption and so on. The high-end mode requires high efficiency, low ineffective energy consumption, low noise, no shock and stress response. Such as the use of air oxygenation system needs to carry out accurate accounting, the use of reasonable technology and accurate design. Promote oxygen enrichment and oxygenation technology to improve the carrying capacity and yield capacity.

5. Tailwater treatment

Aquaculture tail water is rich in inorganic N, P and aquaculture solid waste, direct discharge will not only cause pollution to the environment, but also cause a waste of resources, carrying out the research and development of key ecological purification technology, the construction of ecological purification model has become a hot spot.

6. Temperature control facilities

Although in the current domestic aquaculture, still adopt the "local conditions" farming method. However, with the continuous changes of the market, cross-regional and cross-temperature farming methods have gradually emerged in China. For example, the key to successful multi-batch breeding of South American white shrimp in low temperature areas is to control the temperature of the breeding water body.

Today, in the factory circulating water system, the necessary temperature control equipment is the main part of achieving this cross-regional farming. Relying on the abundant domestic power supply to meet the needs.

Closing remarks

Nowadays, with the growth of global population, Marine pollution and high load of fishery resources, traditional aquaculture fisheries have been unable to meet the increasing demand for high-quality aquatic protein. This is the case, factory recirculating aquaculture will undoubtedly change the future of aquaculture, but also become a circulating water equipment design, manufacturing and other enterprises development opportunities.